Customized Educational Robot Train Platform ABB/Fanuc/Kuka/ Yaskawa/NACHI 6 Axis Industrial Robot Robotic Arm Industrial Picker

Basic Info.

| Drive Mode | Mechanical |

| Application | Welding, Loading, Forging, Dispensing |

| Condition | Old |

| Certification | ISO, CE |

| Transport Package | Wooden Case |

| Specification | Payload25 Max. reach1850 |

| Trademark | ABB/FANUC/YASKAWA/KUKA/NACHI/UR/OTC/EPSON/YAMAHA |

| Origin | China |

| HS Code | 8479509090 |

| Production Capacity | 100PCS/Year |

Packaging & Delivery

Package Size 1000.00cm * 1000.00cm * 1000.00cm Package Gross Weight 200.000kgProduct Description

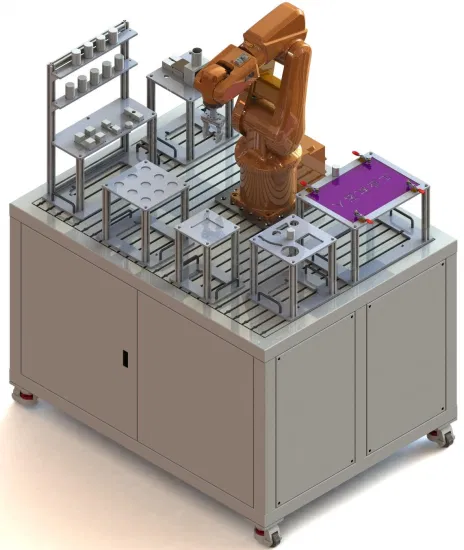

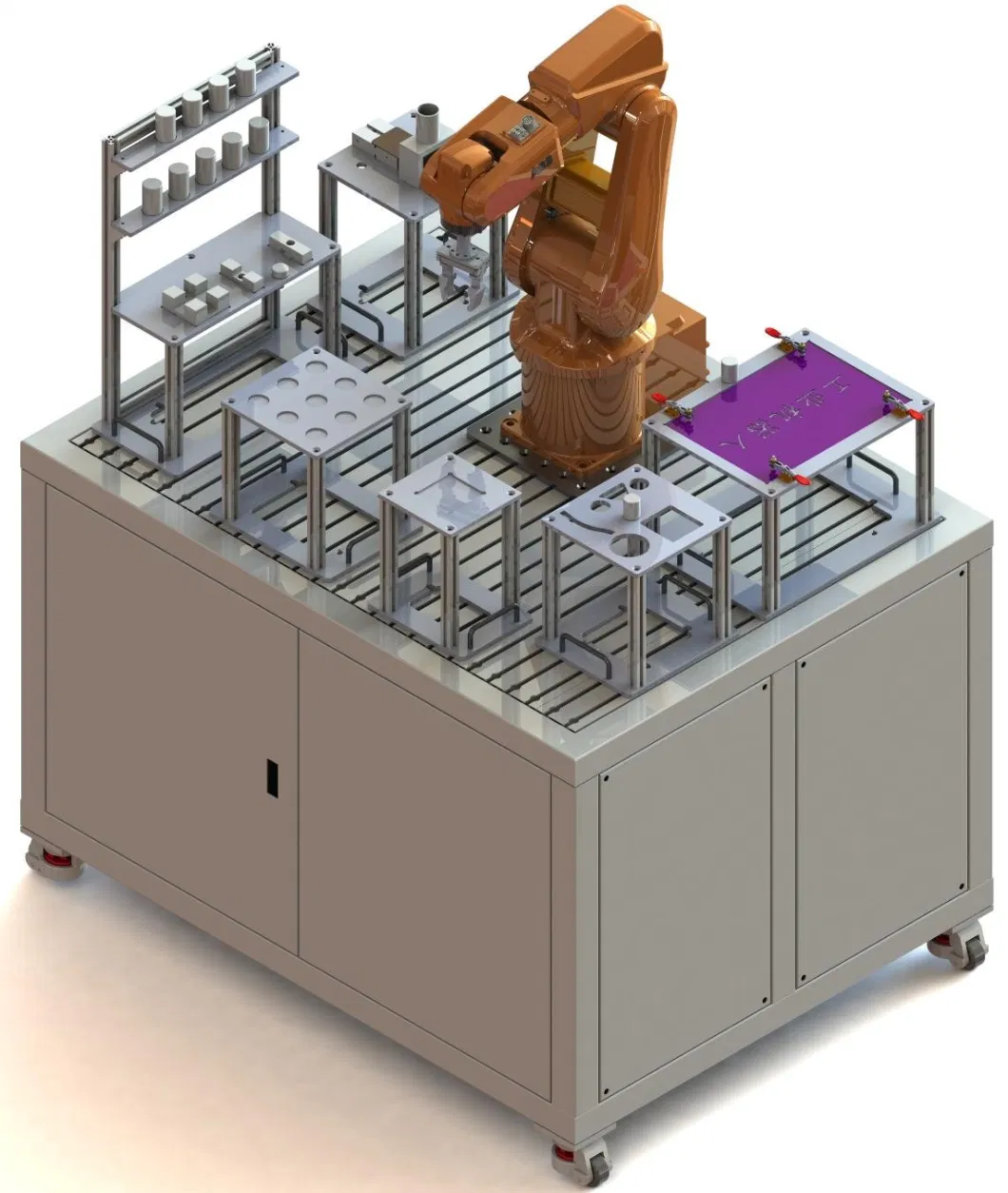

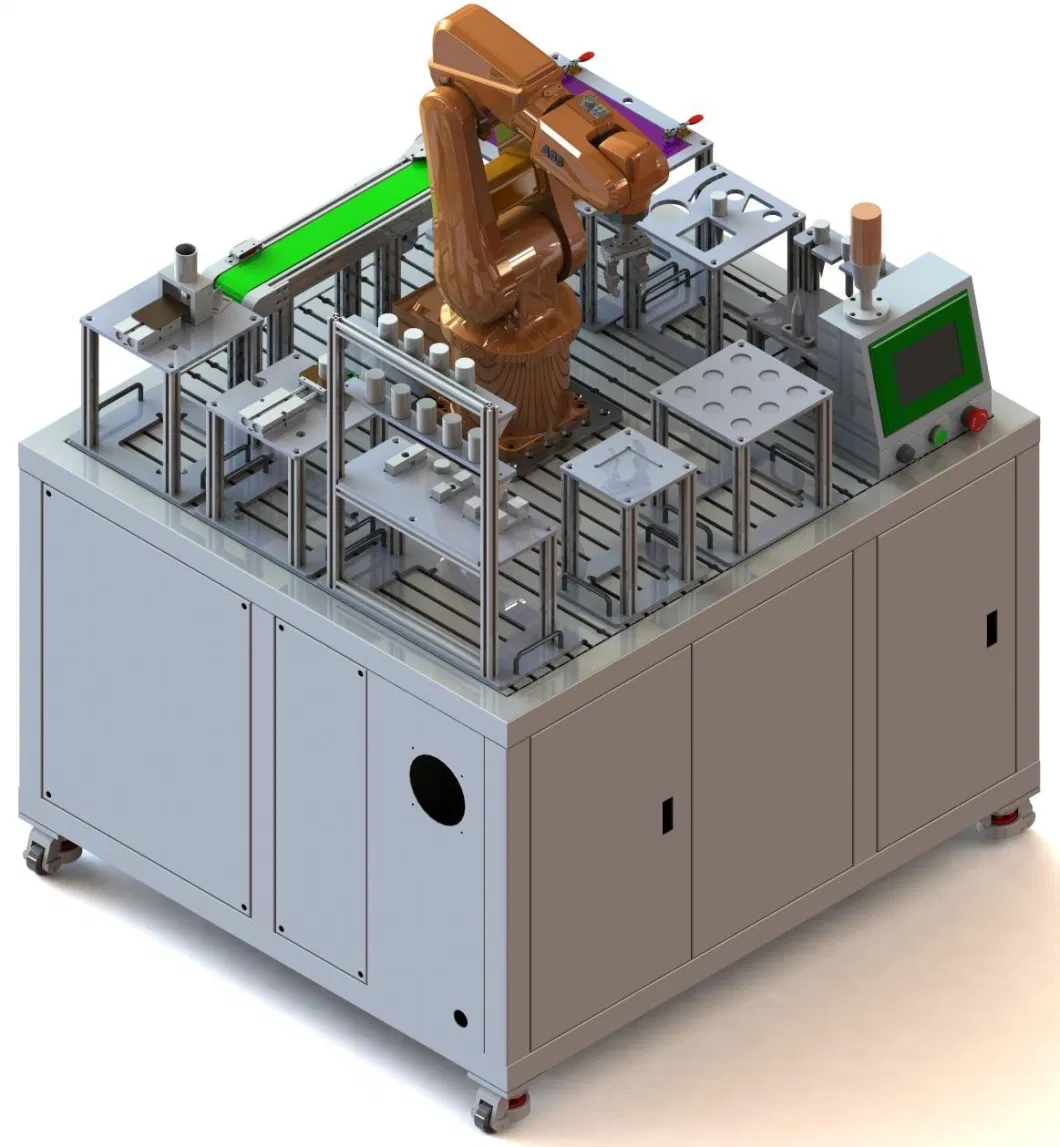

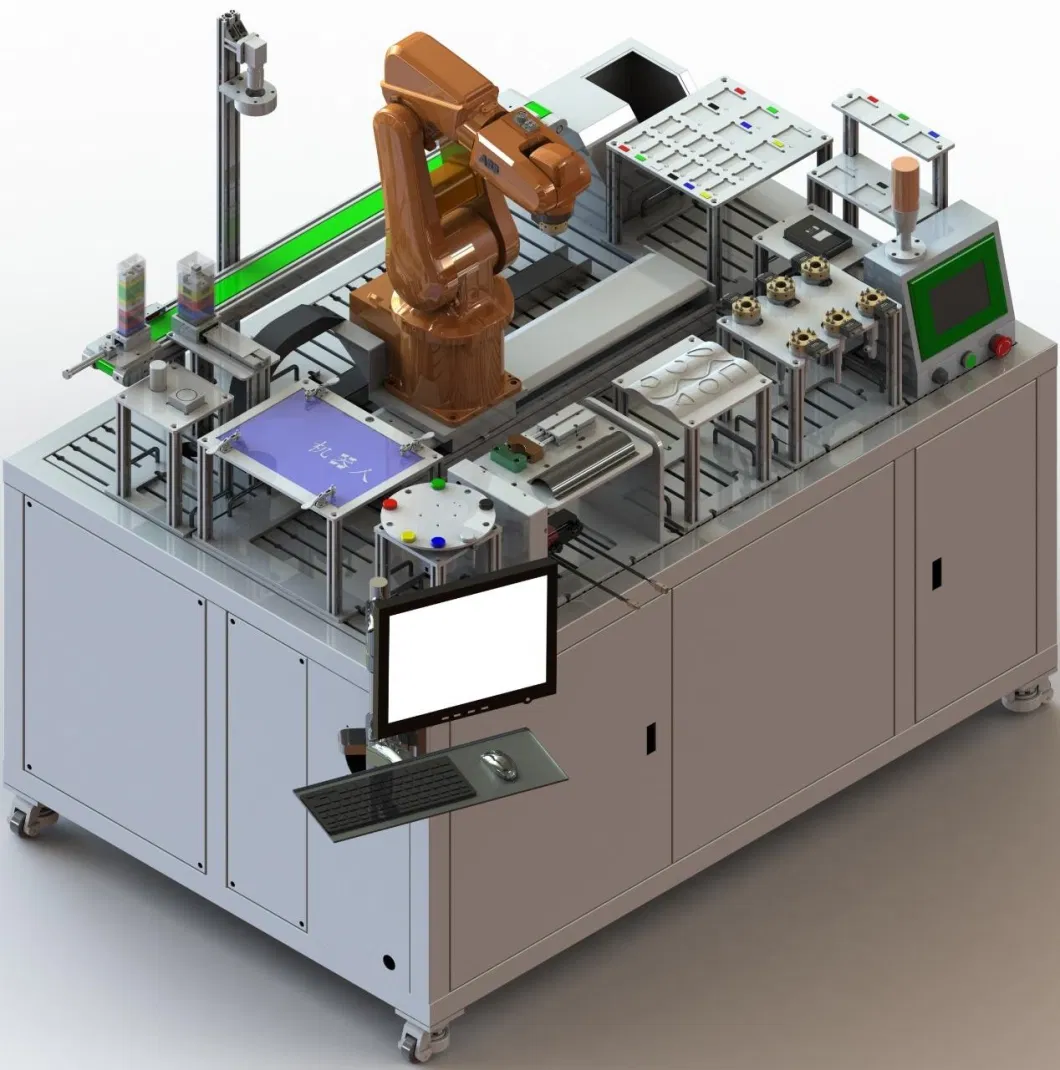

Product DescriptionWe devolop three phase educational platform,primary,medium, senior train modula, also can be customized or assigned, pls feel free to contact us to get more detail.

Robotic Arm Introduction

Our Robot range from owned Brand to ABB,KUKA,YASKAWA,NACHI,ESPON,YAMAHA,KAWASAKI,ETC, from all new to retrofit,covers a variety of robot models loading from 4kg to 500kg,series of products can grasp key processes and process quality,they can be used for various automation operations such as spot welding,arc welding, handling, assembly grinding, polishing, gluing, spraying, machine loading and unloading, injection molding, cutting,etc.Industria Robot Intelligent Products now has the functions of intelligent sensing,intelligent cognition,independent decision-making,and self-control execution. It has carried out in-depth application practice and process integration in various industries.and launched a variety of engineer-series of robot products.Which can be tailored for users.Customize complete and advanced industry solutions with decades verification of engineering application and thousands of proiect engineering experience Industrial Robot provides customers with value-added technical services based on industrial robot products and industrial robot applications with leading technology,which has won the trust and support of customers all over the world.Industrial Robots,focusing on enabling intelligent manufacturing,is a strong partner in your automation field, industrial robots service various national economic industries such as automobiles and car parts,engineering machinery, rail transit,ship building aerospace, metallurgy, electrical, new energy,tobacco, medicine, finance, printing and publishing,etc. Search robot Pls feel free to contact us, we will give you a professtional solution.

Machine Specification| NO. | Name | Description | Primary | Medium | Advanced |

| 1 | Primary table | Fixed module | Y | ||

| 2 | Medium table | Fixed module | Y | ||

| 3 | Advanced table | Fixed module | Y | ||

| 4 | Seven axis module | outer axis | Y | ||

| 5 | primary catch module | parts catch | Y | Y | |

| 6 | Display module | visual info display | Y | ||

| 7 | HMI module | Man-Machine Conversation | Y | Y | Y |

| 8 | Big size POM parts | one set | Y | Y | |

| 9 | mini size POM parts | one set | Y | ||

| 10 | RFID check module | smart storage | Y | ||

| 11 | Positioner module | robot simulation for welding,grinding | Y | ||

| 12 | Up and down the material module for lathe | robot simulation for load/reclaim | Y | ||

| 13 | Stock module | stock/stack/assemble | Y | Y | |

| 14 | Grinding module | robot simulation grinding the parts | Y | ||

| 15 | Tool seat module | robot position calibration | |||

| 16 | Feed module | Feed by the belt | Y | Y | |

| 17 | Draw Module | draw on A4 paper | Y | Y | |

| 18 | Quick change module | quick change tools | Y | ||

| 19 | Assemble&storege module | assemble/store different color tools | Y | ||

| 20 | Stacking module | stack the product | Y | ||

| 21 | plane module | Planar trajectory programming | Y | ||

| 22 | Curve module | Surface trajectory programming | Y | ||

| 23 | visual module | analysis the part on the feed bel | Y | ||

| 24 | Conveyor tracking gluing module | Conveyor belt tracking and gluing demonstration | Y | ||

| 25 | Conveyor feed module 1 | Conveyor belt assembly workpiece supply | Y | ||

| 26 | conveyor feed module2 | Conveyor belt assembly workpiece supply | Y | ||

| 27 | Advanced education conveyor module | workpiece transfer | Y | ||

| 28 | Medium education conveyor module | workpiece transfer | Y |

Company Introduction

Dongguan bodas Intelligent Technology Co., Ltd. is located in the famous manufacturing city of Dongguan, Guangdong. It is a manufacturer of rubber and plastic experimental equipment, post printing packaging equipment and testing equipment integrating R & D, production and sales. The company was established in 2006 and is committed to the development of reliable, easy-to-use equipment to improve the manufacturing quality of products and reduce costs. At present, the company has 6 engineers, 23 processing and assembly technicians, and 4 pre-sales and after-sales personnel. After the integration in 2021, the company's business has been steadily improved and can provide customers with more personalized and efficient equipment. At present, the company covers an area of 1800 square meters. There are 3 CNC machining centers, 8 milling machines, 2 ordinary lathes, 1 surface grinder, 1 large water mill, 1 tapping machine and a cutting machine.

Shipping And Packaging

| Shipping | By sea, or as your requirement to do | |

| Packaging | By Strong Wooden Case | |

FAQ

Q: How to find the machine suitable for my product?

A: Tell us about your product details and packing requirements. 1. What kind of product you would like to treat? 2. The bag/sachet/pouch size of you need for the product packing ( the length, width). 3. The weigh of each pack you need. 4. You requirement for the machines and the bag styleQ: Is engineer available to serve oversea?

A: Yes, but the travel fee is responsible by you. In order to save your cost, we will send you a video of full details machine installation and assist you till the end

Q: How can we make sure about the machine quality after placking the order?

A: Before delivery, we will send you the pictures and videos for you to check the machine quality. And also you can arrange for quality checking by yourself or by your contacts in China

Q: What time for delivery ?

A: Machine about 45days after get your down payment , paper cone as the quantity

Q: Can you explain me the whole transaction process ?

A: 1.Sign the Contact 2.Arrange 50% deposit to our factory 3.Factory arrange production 4.Testing & detecting the machine before shipping 5.Inspected by customer or third agency through online or site test. 6.Arrange the balance payment before shipment

Q: Will you provides the delivery service?

A: Yes. Please inform us of your final destination, we will check with our shipping agent to quote the shipping cost for your reference before delivery.